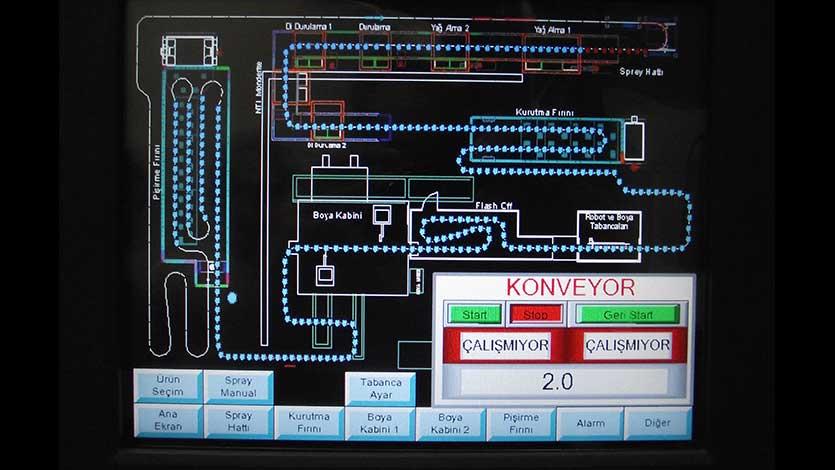

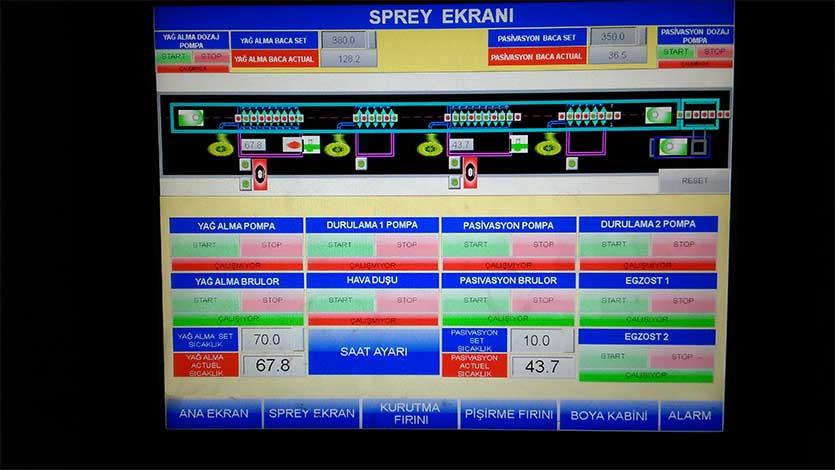

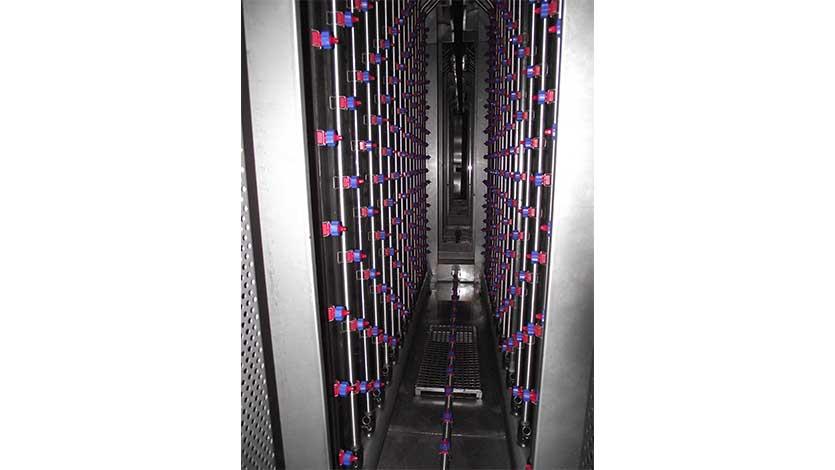

In the spraying pre-treatment method, applying chemicals with a certain pressure on the parts creates big positive differences on paint quality and life span. By cleaning and coating the surface of the part before painting, the paint will retain its first-day quality with out any degradation for long years by strong adhesive forces. Our spray tunnels, with the help of automation systems, allow you to be able to produce automatically and continuously with out any touch.

Tunnel type spray surface cleaning lines consist of parts like spray nozzles, heat exchangers, dosing pumps and ventilating systems. In our spray lines, the AISI 304 – AISI 316 stainless sheets of steel and polypropylene are used. According to needs of our esteemed customers, horizontal belt type conveyor, compact type, and rotary table type automatic plc controlled washing machines can be produced by us.

Some chemicals which are used for surface cleaning must be applied hot. Due to this situation, our company produces cold spray lines as well as natural gas heated, electric heated, liquid fuel heated and water heated spray pre-treatment lines according to the energy source that is planning to be used.